Dassault Syst?mes Delivers Strong 2021 Results, With Fourth Quarter Well Aligned With Guidance

Dassault Syst?mes, today announced IFRS unaudited financial results for the fourth quarter and year ended December 31, 2021. The Group?s Board of Directors approved...

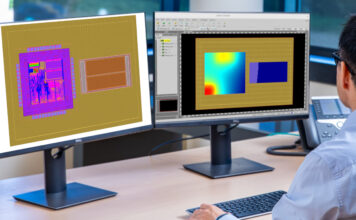

EMA Design Automation Expands Operations in Central Europe

EMA Design Automation?, a full-service provider and innovator of Electronic Design Automation (EDA) systems solutions, today announced it is expanding its global reach with...

Samsung Heavy Industries Builds World?s Largest Containership with Intergraph Smart? 3D

Successful construction of the MOL Triumph cements partnership of technological excellence

Finding the flow creates a new way to 3D-print metal

A team of engineers has developed a new way of 3D-printing metals that could improve on existing, laser-on-powder based methods. It relies on using semi-solid metals that are solid at rest, but can flow when force is applied, making it possible to move through the nozzle of a printer. Researchers at Lawrence Livermore National Laboratory (LLNL) hope that the process could lead to higher-quality and lighter metal parts.

3D Printing with plants is cheaper, stronger and more environmentally friendly

Engineers at MIT have developed a way to use plant cellulose as a feedstock for 3D printers, providing another renewable, biodegradable alternative to popular petroleum-based polymers like ABS currently being used. The researchers also believe printing with cellulose could be cheaper and stronger than other materials and even offer potential antimicrobial properties to boot.

Madrid gets world’s first 3D-printed footbridge

The Institute of Advanced Architecture of Catalonia (IAAC) has designed the world's first 3D-printed pedestrian bridge. Installed in the urban park of Castilla-La Mancha in Alcobendas, Madrid, and made up of eight separate 3D-printed parts, the bridge spans 40 ft (12 m) and measures 5.7 ft (1.75 m) wide.

3Doodler brings 3D pen printing to professionals

3Doodler's 3D printing pens are a lot of fun, and with models already available for hobbyists and kids, they've already proved pretty popular, with more 750,000 units shipping since the first device launched in 2013. Now, the company is taking things into a more serious sphere, releasing the 3Doodler Pro, a brand new pen that aims to provide a more refined experience to professional users such as architects, engineers and fashion designers.

Manufacturing Vertical Dominates CEE Spending

In a recent update to the Worldwide 3D Printing Spending Guide, International Data Corporation (IDC) estimates that organizations in Central and Eastern Europe (CEE) will invest more than $917 million in 3D printing hardware, software, services, and materials this year. IDC expects that 3D printing revenue in the CEE region will post a compound annual growth rate (CAGR) of 28.0% over the 2016?2020 forecast period, reaching $2.30 billion in 2020. Manufacturing, professional services, and education represent the three largest verticals in the forecast update, and are predicted to jointly account for over three-quarters of total CEE 3D printing spending in 2016.

Multi-material 3D printer aimed squarely at professionals

3D printers capable of churning out multi-material, multi-colored objects in a single print run can take up quite a bit of office space, and can also cost a small fortune. Take the Objet500 Connex3 from Stratasys, for example. It's about the size of a chest freezer and you could buy three second gen Panamera's for the same price. French startup Pollen has introduced a capable-looking, high resolution machine for the professional market called Pam, which can handle up to four different materials and comes in at a fraction of the cost of the Stratasys printer.

Mercedes-Benz harnesses 3D printing for on-demand spare parts

While companies like Local Motors are dabbling with the idea of a fully 3D-printed car, bigger manufacturers are embracing the technology on a smaller scale. Mercedes-Benz Trucks is harnessing the on-demand benefits of parts produced in this way, using an environmentally friendly 3D printing process to create spare parts.