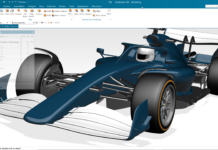

Siemens brings new immersive collaboration, electro-mechanical workflows and new AI-enabled design capabilities to NX

Siemens Digital Industries Software today announced the latest updates to its NX? software from the Siemens Xcelerator portfolio bringing new and enhanced capabilities to...

CATIA certified for 3D PluraView

The 3D software application CATIA from the French company Dassault Syst?mes has already successfully established itself in many industries worldwide: in aerospace, the automotive...

New Heilind distribution centre set to open

Heilind Electronics Europe, a leading global distributor of connectors and electromechanical components, is to open a new state-of-the-art distribution centre early in September 2022...

Dassault Syst?mes Delivers Strong 2021 Results, With Fourth Quarter Well Aligned With Guidance

Dassault Syst?mes, today announced IFRS unaudited financial results for the fourth quarter and year ended December 31, 2021. The Group?s Board of Directors approved...

Samsung Heavy Industries Builds World?s Largest Containership with Intergraph Smart? 3D

Successful construction of the MOL Triumph cements partnership of technological excellence

3DEXPERIENCE World 2024: AI and the Future of Engineering Design

After a long break, I had the wonderful opportunity to attend the 25th Anniversary edition of 3DEXPERIENCE World 2024 by Dassault Syst?mes, which took...

FIA selects Siemens as Official Sustainability PLM Software Supplier

Siemens Digital Industries Software announced today that the Fédération Internationale de l'Automobile (FIA), the governing body of world motor sport and the federation of...

CNCzone takeover to create largest international online platform for production technology

Production tasks are growing in complexity and the requirements ever higher for all personnel in the production process. It is often the...

Hexagon launches Reality Cloud Studio to bring automated digital reality to the cloud

Hexagon AB, the global leader in digital reality solutions combining sensor, software and autonomous technologies, today announced the launch of Reality Cloud Studio, powered...

3Doodler brings 3D pen printing to professionals

3Doodler's 3D printing pens are a lot of fun, and with models already available for hobbyists and kids, they've already proved pretty popular, with more 750,000 units shipping since the first device launched in 2013. Now, the company is taking things into a more serious sphere, releasing the 3Doodler Pro, a brand new pen that aims to provide a more refined experience to professional users such as architects, engineers and fashion designers.